About Global Lift Used Forklifts Surprise

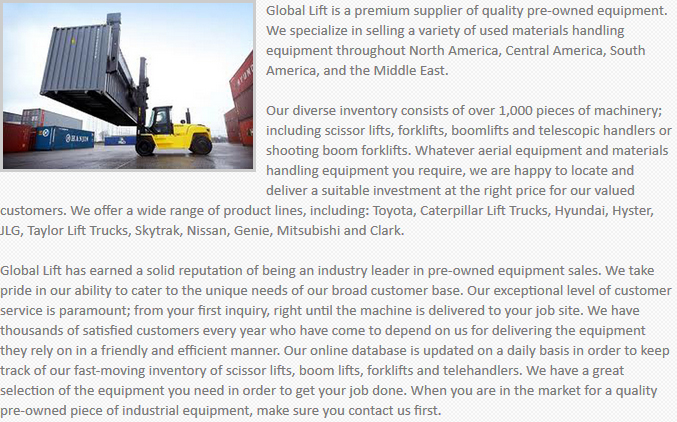

Global Lift Surprise - A forklift purchase is not to be taken lightly. A forklift is a huge capital expenditure, and a complex equipment with a motor strong enough to perform heavy-lifting tasks. The price tag for a forklift varies from ten thousand dollars to thirty thousand dollars, comparable to the cost of a small truck. If buying a second-hand forklift, be certain to have it inspected for potential mechanical issues.

The two kinds of forklift motors are: electric or internal combustion. Forklifts with electric motors are typically more costly compared to forklifts with internal combustion motors. The size of the motor should suit the kind of work for which the forklift will be used. A forklift with a large motor costs more than a forklift with a motor which is smaller.

Motors which use propane or gasoline can lift heavier weights since they are usually stronger than electric motor. The downside is that gas motors tend to develop problems more frequently than electric motors. Depending on the price of gas or propane, gas powered forklifts could be more expensive to run compared to electric powered forklifts.

Some reputable manufacturers of forklifts are Crown Equipment Corp., Mitsubishi Caterpillar, NACCO Industries and Toyota Industries. Before deciding, research the various manufacturers and the availability of parts. Reviews, testimonials and prices could be found on line.

Since 1917, essential tools utilized in commercial businesses and industry are forklifts. During its history the forklift has evolved through various kinds, from a tractor with an attached platform to a specialized high-tech equipment. Forklift tires have also evolved into particular tires, with various kinds designed to meet particular applications.

A cushion tire is made of solid polyurethane or rubber and is suitable for indoor applications on smooth surfaces. The cushion tire tread is bonded or pressed onto the steel ring of the tire. Cushion tires are rated for different load capacities and for ease of steering. Cushion tires are usually utilized in warehouse settings.

Pneumatic forklift tires are filled with air or foam. They are available in two kinds: bias or radial. Depending on the use, they come with various sidewall protection, tread depths and weight. Pneumatic forklift tires that are filled with foam maintain constant pressures and are less prone to punctures. Pneumatic tires are commonly utilized outdoors on surfaces which are rough and uneven.

The comfortable ride which pneumatic tires offer together with the puncture resistance which solid tires provide are the combined features of Solid Pneumatic Hybrid Tires. They are a good option to the outdoor pneumatic tire.

Big rubber tires, that could be foam, solid or pneumatic, are utilized on wheel loader forklifts. These tires are suitable for moving and loading bulk items into processing machines or onto trucks. Big flotation pneumatic tires are suited for masted rough terrain forklifts usually utilized at construction locations, auto recyclers and lumberyards.

Powered lift trucks called forklifts are utilized in almost every industry to move heavy products and materials. The forklift is a very tough and dependable machinery which has become important tools in a lot of warehouse and construction environments. Forklift units differ depending on the type of fuel which is utilized to power the lift truck and the kind of work setting.

Electric powered lift trucks are great for indoor settings, or in places with limited ventilation because they make no exhaust fumes. They are designed with industrial strength batteries. Since the electric forklift batteries require charging, the worksite would require a charging station. The batteries are durable and could be re-charged up to one thousand five hundred times before they need to be replaced. The charging station must be situated in a ventilated area and include an emergency eyewash station and an acid spill kit.

Liquid propane powered forklifts are frequently used in modern industrial operations as propane has some benefits over electric and diesel. Propane models are cleaner to use than diesel-powered units. There is no down time needed to recharge an industrial battery, and the cost for propane is less compared to the cost of electricity. A forklift propane tank can be easily and quickly refueled by changing out the empty tank with a full tank. Usually an off-site supplier refills the empty tank, making refueling very efficient and safe.

For outdoor applications and rough terrain, the gas and diesel forklifts are the equipment of choice. These equipment are quite common on construction sites and in lumber yards. Their disadvantages include fairly high maintenance needs, odorous exhaust and fairly high fuel costs. Their advantages include dependability in tough conditions and a longer lifespan than other units. Diesel and gasoline units should be refueled at a supply station on site which meets health and safety policies.

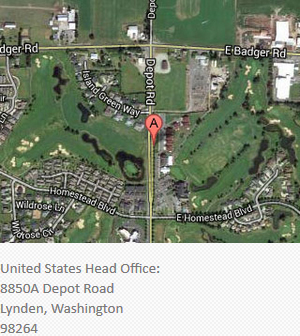

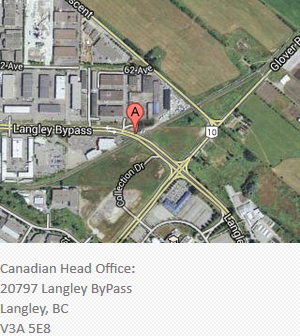

Contact Info

Questions or Comments